Aluminium door infill panels are the ideal product for discerning customers thanks to their excellent properties. The noble impression of them is enhanced by the dimensional stability of the aluminium-magnesium alloy used. GAVA Aluminium infill panels are characterized by modern design and precision machining on the most modern laser and CNC technologies.

A durable paint is applied to the surface of the aluminium alloy by powder coating technology and subsequent firing at 200 °C in a curing furnace.

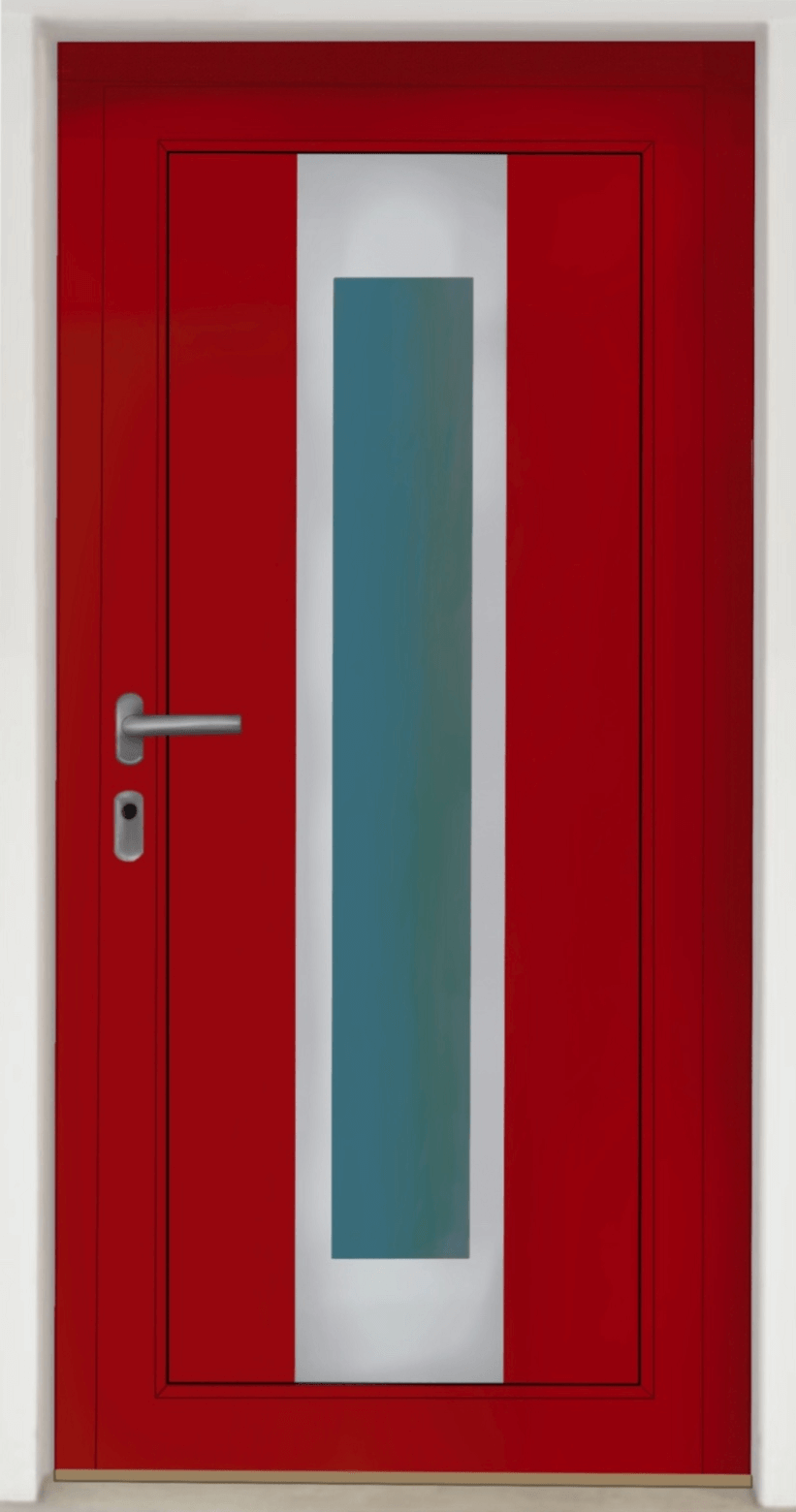

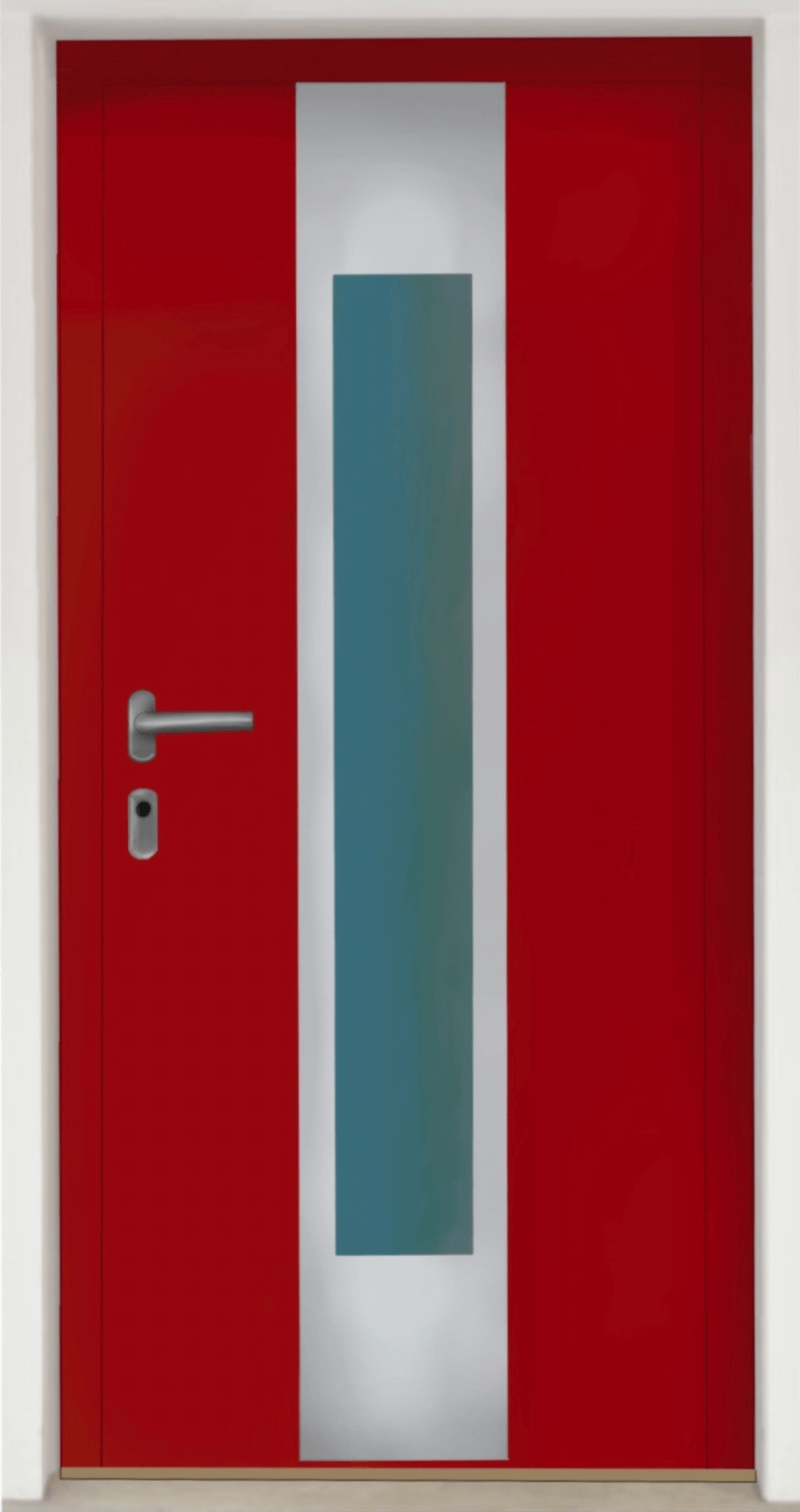

The design itself consists of a combination of straight or geometrically milled grooves, glazed surfaces and stainless steel appliqué or marquetry.

We supply these elements in a modern black colour, or the popular stainless steel design.

It is also possible to choose from appliqué designs using flat bar profiles or welded frames produced from our original embossed profile. Infill panels created by engraving coloured surfaces or combined with appliqué are a true jewel in doors.

Black or stainless steel metal design elements are ideal to match with the door pull installed in the part of the infill panel with the same colour.

Ability to match the colour on the profile system, after the exact specification of the colour also used for painting door profiles

Colour per the RAL colour scale

Door infill panels are 24 mm to 48 mm thick, please call for a different thickness.

The sophisticated Core F is used for any thickness door infill panel of 36 mm or higher.

Attention: Door infill panels are shipped with a protective foil for transport, and this must be removed immediately after door installation.

Infill panel pull

Can be installed directly on the door infill panel. When placing an order, please specify the location of the door pull to allow the proper reinforcement to be installed under the pull during manufacturing

Milled groove

A milling cutter creates a grove by machining the surface material following a computer design

Preview

Raised infill panels are the perfect choice for more discerning clients who do not want to miss the opportunity to feature a unique design and refined elegance in their entry door. We would be happy to provide you with an original solution verified by thousands of infill panels and years of experience.

Exceptional design and elaborate design allows us to divide the raised infill panels into two basic categories:

Exterior

Interior

Single - sided raised door

infill panels

This type of door infill panel gives an entry door the best opportunity to shine, especially when viewed from the exterior. The infill panel is not installed in the door sash as in the case of inset infill panels; instead, it covers the exterior side of the door sash up to its visible exterior edges. The doors maintain an elegant, solid appearance that is not framed by the thick frame of the door sash. This will give your door an exclusive look that combines elements of security and elegance.

By choosing a raised door infill panel, your entry door will become a characteristic element of your home that you will be justifiably proud of.

Advantages compared to inset infill panels

From the exterior side, the use of high quality composite material comprised of multiple layers of fibreglass is joined using a sophisticated epoxy resin. This material provides high toughness and strength, with minimal thermal expansion. The door infill panel is not installed into the door sash and instead it is glued up to its visible edges. The thick frame no longer degrades the design

From the interior, the door infill panel design is lined by the door sash frame. The infill panel filling is glazed around the perimeter with glazing trim with seals, the same as the inset infill panel. If you want the same design from both the exterior and interior, we recommend a double-sided raised door infill panel

Thermal insulation properties are often many times better than an inset infill panel as the thickness of the door infill panel can be much larger compared to typical inset door infill panels

The infill panel is specially designed to be independent of external influences. Forces exerted by the door infill panel on the exterior part of the profile system are minimised

Door infill panel glazing is constructed so as to provide expansion without the risk of compromising the adhesive bond between the exterior surface panel and the glazing

Accident protection - door infill panels are typically only glued to the door sash, which poses an injury hazard, and there is the risk of the glue bond degrading or failing as a result of temperature differences. Door infill panels typically have large dimensions and could cause serious injury should it fall off. For this reason, we use our designed and proven method of anchoring the infill panel, which allows expansion, and ensures the infill panel cannot simply fall out

Burglary protection - simple de-lamination of the door infill panel is simply impossible. Every raised door infill panel is secondarily glued to the interior side of the door sash around the perimeter of the non-expansion part of the core

The door has a more solid and exclusive appearance

Exterior

Interior

Double - sided raised door infill

panels with the duo system

All HPL door infill panels are offered to our customers as double-sided raised door infill panels with the DUO SYSTEM. This door infill panel allows the beauty of your entry door to shine both inside and outside. The infill panel is not inset in the sash and instead it covers the sash up to its visible exterior perimeter, which means the door sash no longer compromises the design of the door infill panel itself. GAVA door infill panels combined with a quality profile system from your window supplier in this configuration represent a top-of-the-line entry door product in terms of technology, design, safety, thermal insulation, soundproofing and the ability to use larger dimensions.

Advantages compared to inset infill panels

From the exterior and interior side, the use of high quality composite material comprised of multiple layers of fibreglass is joined using a sophisticated epoxy resin. This material provides high toughness and strength, with minimal thermal expansion. The door infill panel is not installed into the door sash and instead it is glued up to its visible edges. The thick frame no longer degrades the design

The rigorously proven technically advanced DUO SYSTEM is a unique and complex system of layers forming the core of the infill panel. Several internal layers provide thermal insulation and soundproofing, together with expansion and security layers. The outer surface layers ensure the design. In addition, the system can be disassembled if necessary, allowing for service.

The exterior part - Core F - reduces the forces exerted by the door infill panel on the door sash

The middle part - is mechanically anchored to the interior part of the profile system and is the safety basis of the whole construction, the so-called DUO SYSTEM

The interior part - of the core is independent of any crimping and has a serviceable (removable) layer

Door infill panel glazing is designed so as to provide sufficient expansion without the risk of compromising the adhesive bond between the exterior surface panel and the glazing

Accident protection - door infill panels are typically only glued to the door sash, which poses an injury hazard, and there is the risk of the glue bond degrading or failing as a result of temperature differences. Door infill panels typically have large dimensions and could cause serious injury should it fall off. For this reason, we use our designed and proven method of anchoring the infill panel, which allows expansion, and ensures the infill panel cannot simply fall out

Burglary protection - simple de-lamination of the door infill panel is simply impossible. Every glued door infill panel with the GAVA DUO system is mechanically anchored around the perimeter of the central core to the interior part of the sash. Two reinforcing panels, one composite, and the other steel, that form the central part of the infill panel core, provide maximum security

Door manufacturers receive a precisely designed solution for the specific profile system and specific dimensions from GAVA Plast. This eliminates the risk of the manufacturer experiencing defects in the mating between the infill panel and the sash. The manufacturer also receives a ready-made set with designed and correctly arranged securing points

We can also supply the door supplier with a glueing kit together with instructions specifically designed for glueing these systems while maintaining the required expansion properties of the infill panel itself.

Attention! It is critical to maintain the expansion gap at the connection of the exterior plate with the sash profile by using a glueing system that maintains the expansion properties of the infill panel

|

| GAVA brown patina |

| RAL 1000 |

| RAL 1003 |

| RAL 1006 |

| RAL 1012 |

| RAL 1015 |

| RAL 1018 |

| RAL 1021 |

| RAL 1027 |

| RAL 1033 |

| RAL 2001 |

| RAL 2004 |

| RAL 2010 |

| RAL 3000 |

| RAL 3003 |

| RAL 3007 |

| RAL 3012 |

| RAL 3015 |

| RAL 3018 |

| RAL 3027 |

| RAL 4002 |

| RAL 4005 |

| RAL 4008 |

| RAL 5001 |

| RAL 5004 |

| RAL 5008 |

| RAL 5011 |

| RAL 5014 |

| RAL 5018 |

| RAL 5021 |

| RAL 5024 |

| RAL 6002 |

| RAL 6005 |

| RAL 6008 |

| RAL 6011 |

| RAL 6014 |

| RAL 6017 |

| RAL 6020 |

| RAL 6024 |

| RAL 6027 |

| RAL 6032 |

| RAL 7000 |

| RAL 7003 |

| RAL 7006 |

| RAL 7010 |

| RAL 7013 |

| RAL 7021 |

| RAL 7024 |

| RAL 7031 |

| RAL 7034 |

| RAL 7037 |

| RAL 7040 |

| RAL 7044 |

| RAL 8002 |

| RAL 8007 |

| RAL 8012 |

| RAL 8016 |

| RAL 8022 |

| RAL 8025 |

| RAL 9002 |

| RAL 9005 |

| RAL 9016 |

| Concrete gray GD802 D8 lamination detail |

| RAL 1001 |

| RAL 1004 |

| RAL 1007 |

| RAL 1013 |

| RAL 1016 |

| RAL 1019 |

| RAL 1023 |

| RAL 1028 |

| RAL 1034 |

| RAL 2002 |

| RAL 2008 |

| RAL 2011 |

| RAL 3001 |

| RAL 3004 |

| RAL 3009 |

| RAL 3013 |

| RAL 3016 |

| RAL 3020 |

| RAL 3031 |

| RAL 4003 |

| RAL 4006 |

| RAL 4009 |

| RAL 5002 |

| RAL 5005 |

| RAL 5009 |

| RAL 5012 |

| RAL 5015 |

| RAL 5019 |

| RAL 5022 |

| RAL 6000 |

| RAL 6003 |

| RAL 6006 |

| RAL 6009 |

| RAL 6012 |

| RAL 6015 |

| RAL 6018 |

| RAL 6021 |

| RAL 6025 |

| RAL 6028 |

| RAL 6033 |

| RAL 7001 |

| RAL 7004 |

| RAL 7008 |

| RAL 7011 |

| RAL 7015 |

| RAL 7022 |

| RAL 7026 |

| RAL 7032 |

| RAL 7035 |

| RAL 7038 |

| RAL 7042 |

| RAL 8000 |

| RAL 8003 |

| RAL 8008 |

| RAL 8014 |

| RAL 8017 |

| RAL 8023 |

| RAL 8028 |

| RAL 9003 |

| RAL 9010 |

| RAL 9017 |

| RAL 1002 |

| RAL 1005 |

| RAL 1011 |

| RAL 1014 |

| RAL 1017 |

| RAL 1020 |

| RAL 1024 |

| RAL 1032 |

| RAL 2000 |

| RAL 2003 |

| RAL 2009 |

| RAL 2012 |

| RAL 3002 |

| RAL 3005 |

| RAL 3011 |

| RAL 3014 |

| RAL 3017 |

| RAL 3022 |

| RAL 4001 |

| RAL 4004 |

| RAL 4007 |

| RAL 5000 |

| RAL 5003 |

| RAL 5007 |

| RAL 5010 |

| RAL 5013 |

| RAL 5017 |

| RAL 5020 |

| RAL 5023 |

| RAL 6001 |

| RAL 6004 |

| RAL 6007 |

| RAL 6010 |

| RAL 6013 |

| RAL 6016 |

| RAL 6019 |

| RAL 6022 |

| RAL 6026 |

| RAL 6029 |

| RAL 6034 |

| RAL 7002 |

| RAL 7005 |

| RAL 7009 |

| RAL 7012 |

| RAL 7016 |

| RAL 7023 |

| RAL 7030 |

| RAL 7033 |

| RAL 7036 |

| RAL 7039 |

| RAL 7043 |

| RAL 8001 |

| RAL 8004 |

| RAL 8011 |

| RAL 8015 |

| RAL 8019 |

| RAL 8024 |

| RAL 9001 |

| RAL 9004 |

| RAL 9011 |

| RAL 9018 |